Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Understanding Tripod Bearings and Their Pricing

When it comes to the smooth operation of machinery, the role of bearings cannot be overstated. Among the various types of bearings, tripod bearings hold a special place due to their unique design and functionality. This blog post delves into the world of tripod bearings, exploring their importance, applications, and factors affecting their price. By the end, you'll have a comprehensive understanding of tripod bearings and why their pricing can vary significantly.

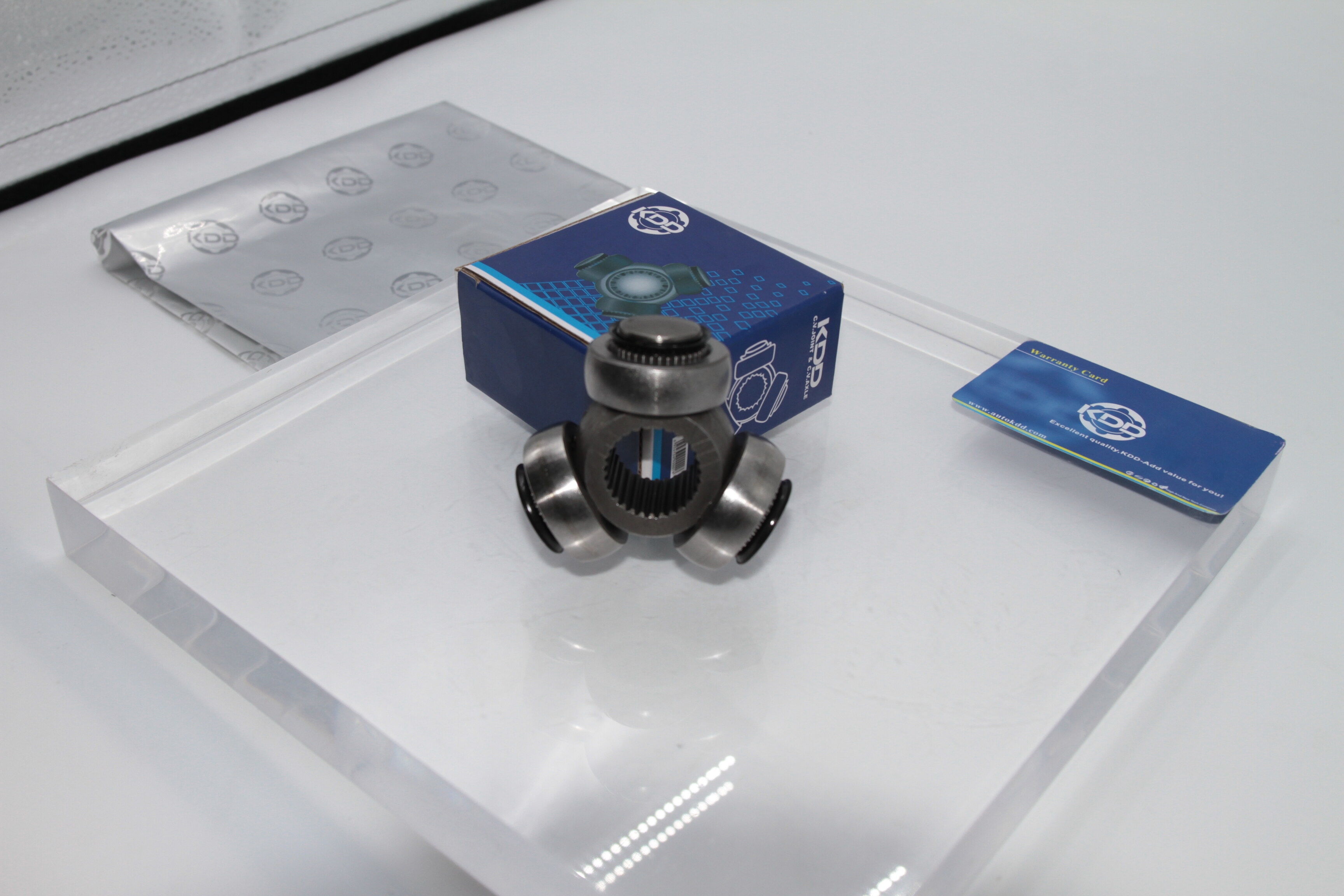

What Are Tripod Bearings?

Tripod bearings, often found in automotive and industrial applications, are crucial components in constant velocity (CV) joints. A CV joint is responsible for transmitting power from a vehicle's engine to its wheels, enabling smooth and consistent wheel rotation. Tripod bearings facilitate this process by reducing friction and wear, thus enhancing the longevity and performance of the CV joints.

The name "tripod bearing" comes from their distinctive design, featuring three bearing rollers attached to a central hub. This setup allows the bearing to accommodate axial and radial loads, as well as angular misalignments, making them ideal for high-performance applications where precision and durability are paramount.

Applications of Tripod Bearings

Tripod bearings are predominantly used in the automotive industry, particularly in front-wheel-drive vehicles. They are essential for the efficient functioning of CV joints, which are integral to the vehicle's drive shaft. By ensuring the smooth transmission of power to the wheels, tripod bearings contribute to the overall driving experience, providing stability and reducing vibrations.

Beyond automotive applications, tripod bearings are also utilized in various industrial machinery. Their ability to handle high loads and compensate for misalignments makes them valuable in manufacturing processes, where precision and reliability are crucial.

Factors Influencing Tripod Bearing Price

The price of tripod bearings can vary widely, influenced by several key factors. Understanding these factors can help buyers make informed decisions and find the best value for their needs.

1. Material Quality

The quality of materials used in manufacturing tripod bearings significantly impacts their price. Bearings made from high-grade steel or specialized alloys tend to be more expensive due to their enhanced durability and performance. These materials are designed to withstand high stress and reduce wear, ensuring a longer lifespan for the bearing.

2. Manufacturing Precision

The manufacturing process and the precision with which tripod bearings are made also affect their cost. Bearings that are produced using advanced machining techniques and stringent quality control measures are likely to be more expensive. This is because higher precision reduces the likelihood of defects and ensures optimal performance, particularly in high-stress applications.

3. Brand and Reputation

Brand reputation plays a significant role in determining the price of tripod bearings. Established brands with a history of producing reliable and high-quality bearings often command higher prices. While these bearings may come with a premium price tag, they offer the assurance of quality and performance, which can be worth the investment for critical applications.

4. Load Capacity and Size

The load capacity and size of tripod bearings are critical factors that influence their price. Bearings designed to handle higher loads and larger sizes generally cost more due to the additional material and engineering required. It's essential to select a bearing that matches the specific load requirements of the application to ensure both performance and cost-effectiveness.

5. Customization and Special Features

Custom bearings or those with special features, such as enhanced sealing or corrosion resistance, typically come at a higher cost. Customization allows the bearing to be tailored to specific applications, offering advantages like improved performance and longevity in unique operating conditions.

Tripod Bearing Price Trends

Understanding the trends in tripod bearing prices can help buyers anticipate market fluctuations and make informed purchasing decisions. Several factors contribute to price trends, including raw material costs, technological advancements, and market demand.

1. Raw Material Costs

Fluctuations in the prices of raw materials, such as steel and alloys, directly impact the cost of tripod bearings. When raw material prices rise, manufacturers may pass on the increased costs to consumers, leading to higher bearing prices. Conversely, a drop in raw material costs can result in lower prices for tripod bearings.

2. Technological Advancements

Advancements in manufacturing technology can influence the price of tripod bearings. Innovations that enhance production efficiency and precision can reduce manufacturing costs, potentially leading to more affordable bearings. Additionally, new materials and design improvements can offer better performance at competitive prices.

3. Market Demand

The demand for tripod bearings in various industries affects their pricing. In periods of high demand, prices may increase due to the pressure on supply chains. Conversely, when demand is low, manufacturers may lower prices to stimulate sales and maintain market share.

Tips for Buying Tripod Bearings

When purchasing tripod bearings, it's essential to consider both quality and price to ensure you get the best value for your investment. Here are some tips to help you make an informed decision:

1. Assess Your Needs: Determine the specific requirements of your application, including load capacity, operating environment, and performance expectations. This will help you choose the right bearing without overspending on unnecessary features.

2. Research Brands: Look for reputable brands known for their quality and reliability. While these bearings may cost more, they often provide better performance and longevity, reducing the need for frequent replacements.

3. Compare Prices: Don't settle for the first option you find. Compare prices from multiple suppliers to ensure you're getting a competitive deal. Consider reaching out to manufacturers directly for bulk purchases or customized solutions.

4. Check Reviews and Testimonials: Customer reviews and testimonials can provide valuable insights into the performance and reliability of tripod bearings. Look for feedback from users with similar applications to gauge the bearing's suitability for your needs.

5. Consider After-Sales Support: Choose suppliers that offer robust after-sales support, including warranties and technical assistance. This can provide peace of mind and ensure you have access to help if any issues arise.

Conclusion

Tripod bearings are essential components in various automotive and industrial applications, offering the ability to handle high loads and misalignments with precision. The price of tripod bearings is influenced by factors such as material quality, manufacturing precision, brand reputation, load capacity, and customization options. By understanding these factors and following the tips provided, you can make informed decisions and find the best tripod bearings to meet your needs and budget.

Whether you're a vehicle manufacturer, an industrial engineer, or simply someone curious about the intricacies of machinery, understanding the dynamics of tripod bearing prices will equip you with the knowledge to navigate this critical aspect of engineering with confidence.